Indoor air quality has been a problem in the US for decades and is getting worse every year. The recent pandemic has added more contagious microorganisms to the growing list of contaminants. These contaminants gather in the air you breathe, on the surfaces you touch, and lead to the unpleasant odors you may experience.

The EPA has ranked indoor air pollution among the top five environmental dangers. EPA studies have found indoor air pollutants were generally two to five times greater than outdoor pollution levels. These dangerous indoor pollutants can include harmful microorganisms, mold, pollen, radon, VOC’s, phthalates, PBDE’s , and even pet dander. Poor indoor air quality in your office can result in dry eyes, headaches, nasal congestion, fatigue, nausea, and more serious health issues such as asthma, lung infections, and even lung cancer. The pandemic has brought to light this problem and how important it is to include a system in your work or play space that will sanitize the air and surfaces contaminated by pollutants and microorganisms 24hrs a day while occupied.

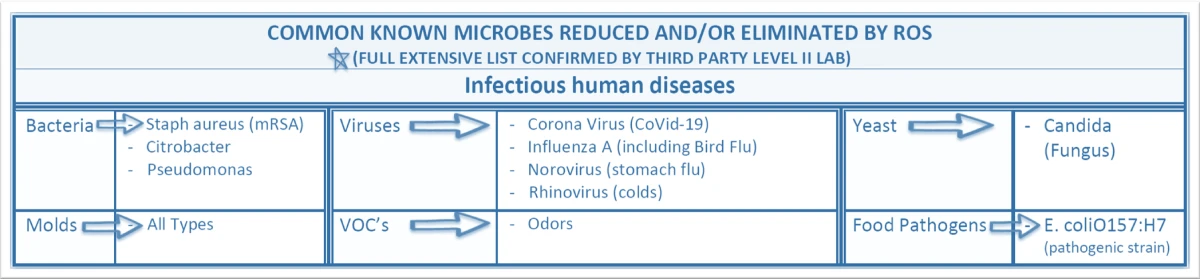

We have great news! MaxClean 756 has the solution with the AirROS hospital grade systems. By upgrading your HVAC system with this industry leading technology and better filtration. You will breathe easier, feel safer, and live better while enjoying a fresh, clean smell, even if you have strong odors to manage. Working with your HAVC system, our commercial or industrial grade air purifying ROS systems send out an army of reactive oxygens to help clean and sanitize the air you breathe and surfaces you touch throughout your work place 24hrs a day. The air purifying system is totally organic and green. It will protect your environment and has a clinically proven 99% cleaner air and surfaces, while improving odor control. Ask your environmental consultant or your HVAC company to install our AirROS hospital grade unit today with an upgraded high MERV filter and create the conference you have control of your environment.

IT’S TIME YOU TAKE CONTROL OF THE SPACE YOU WORK AND PLAY IN!